Facing talent shortage, Taiwanese chip test firm ASE boosts automation

2022.09.28 01:07

[ad_1]

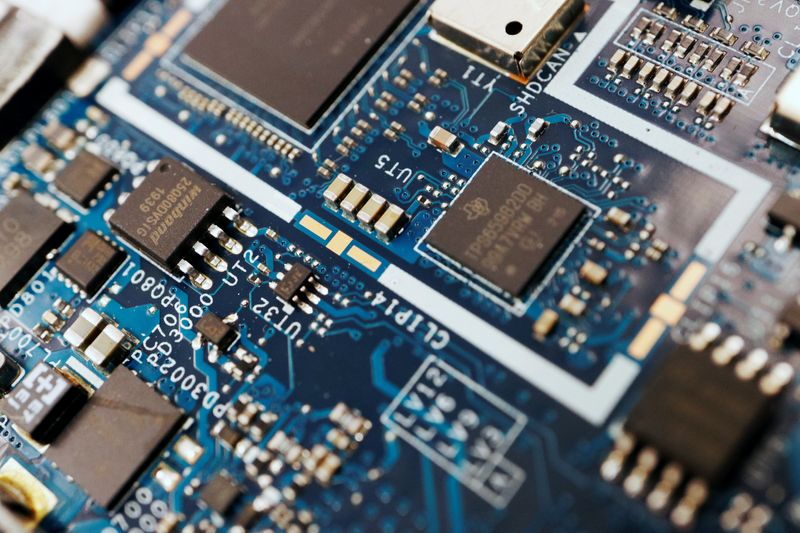

© Reuters. FILE PHOTO: Semiconductor chips are seen on a circuit board of a computer in this illustration picture taken February 25, 2022. REUTERS/Florence Lo/Illustration

By Sarah Wu

TAIPEI (Reuters) – Taiwan’s ASE Technology Holding Co (NYSE:) Ltd, one of the world’s largest semiconductor testing and packaging firms, said on Wednesday that it would build a more advanced smart factory, as the industry continues to grapple with a labour shortage.

The new factory in Kaohsiung, powered by U.S. chip designer Qualcomm (NASDAQ:) Inc’s Snapdragon system, will be the first in the world to deploy a “5G mmWave new radio-dual connectivity standalone” network to improve speed, stability and equipment efficiency, the company said, marking the latest advance in ASE’s automation push.

Apple Inc (NASDAQ:) supplier ASE, which began investing in automated factories in 2015, told Reuters it plans to build 10 smart factories this year, reaching a total of 37 smart factories in Taiwan by the end of the year.

“To counter the talent crunch and adapt to diverse customer requirements, ASE is accelerating its adoption of smart manufacturing technologies including automation,” the company said in a statement.

The talent shortage in the semiconductor industry remains a top concern, executives from companies throughout the chip supply chain from design to manufacturing have told Reuters.

Chip companies in Taiwan have been rapidly expanding in recent years, spurred in part by a pandemic-induced surge in demand for chips, and face fierce competition from local and foreign companies recruiting from a shrinking pool of engineers.

Taiwan’s government last year partnered with industry to establish specialised “chip schools” to boost engineering talent for the prized sector on the island, home to the world’s largest contract chipmaker Taiwan Semiconductor Manufacturing Co Ltd (TSMC).

“We hope to lead by example and inspire more industry players to contribute to building a resilient global smart manufacturing and equipment cluster,” ASE Chief Executive Tien Wu said in a statement.

[ad_2]

Source link